Fire safety remains a critical concern for commercial and residential buildings worldwide. A fireproof door serves as one of the most essential safety barriers, designed to prevent fire spread and provide safe evacuation routes during emergencies. However, the effectiveness of these life-saving installations depends heavily on proper maintenance and regular inspection protocols. Without adequate care, even the highest-quality fire-rated doors can fail when needed most, potentially compromising building occupants and property.

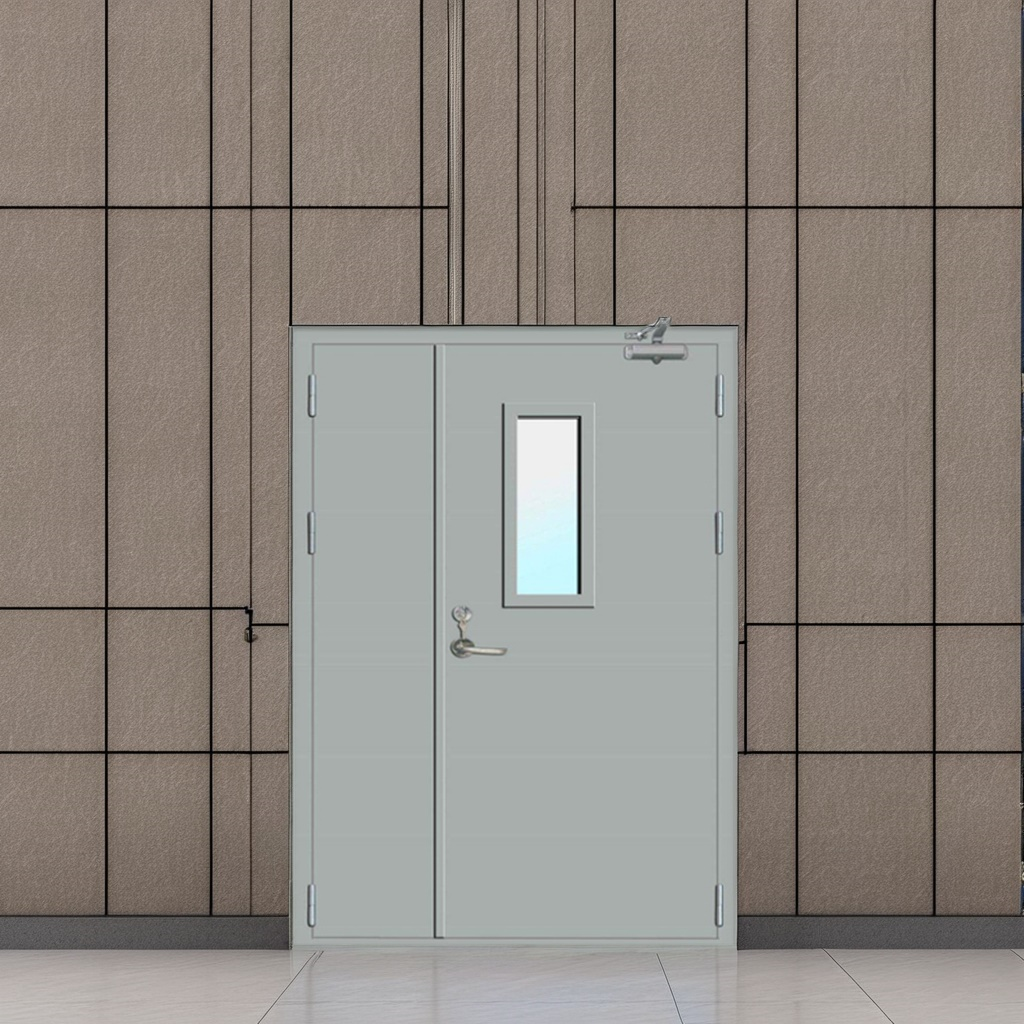

Understanding the complexities of fire door maintenance requires knowledge of various components, materials, and compliance standards. Each fireproof door system consists of multiple elements working together to achieve its fire rating, including the door leaf, frame, seals, hardware, and closing mechanisms. Regular maintenance ensures these components continue functioning as designed, maintaining the door's integrity and fire resistance capabilities throughout its operational lifespan.

Understanding Fireproof Door Components

Door Construction Materials

Modern fireproof door construction utilizes various materials engineered to withstand extreme temperatures and structural stress. Steel remains the most common material due to its strength, durability, and cost-effectiveness. These doors typically feature mineral-filled cores that expand when exposed to heat, creating an insulating barrier that maintains structural integrity. The core materials often include vermiculite, perlite, or other fire-resistant compounds that provide thermal protection while maintaining the door's weight distribution.

Wood-based fire doors incorporate specially treated timber with fire-retardant chemicals and mineral cores. These doors offer aesthetic advantages in certain applications while maintaining required fire ratings. The treatment process involves pressure-impregnating the wood with flame-retardant chemicals that reduce combustibility and slow fire spread. Composite materials combine multiple elements to achieve specific performance characteristics, often incorporating steel reinforcement with insulating cores and protective outer layers.

Hardware and Sealing Systems

Fire door hardware must meet stringent standards to ensure proper operation during emergency conditions. Self-closing mechanisms utilize spring hinges or door closers that automatically return the door to its closed position after opening. These devices require regular adjustment and lubrication to maintain consistent closing force and speed. The closing mechanism must overcome normal air pressure differences and ensure complete door closure without excessive force that might impede evacuation.

Intumescent seals expand when exposed to heat, creating a barrier that prevents smoke and flame penetration around door edges. These seals require periodic inspection for damage, wear, or contamination that could affect their expansion properties. Cold smoke seals work in conjunction with intumescent materials to prevent smoke infiltration at normal temperatures. Door hardware including hinges, locks, and panic devices must maintain their functionality under both normal conditions and during fire exposure.

Regular Inspection Protocols

Visual Assessment Procedures

Systematic visual inspections form the foundation of effective fireproof door maintenance programs. Trained personnel should examine each door monthly, looking for signs of damage, wear, or improper operation. The inspection process begins with checking the door's general condition, including surface integrity, alignment, and closure gaps. Any dents, cracks, or warping could compromise the door's fire resistance and require immediate attention from qualified technicians.

Frame condition assessment involves examining the entire perimeter for damage, loose fasteners, or gaps that could allow fire or smoke penetration. The frame must remain properly anchored to the surrounding structure, with no signs of movement or separation. Door seals require careful examination for cuts, tears, or missing sections that could reduce their effectiveness. Visual inspection should also verify that all required fire door signage remains in place and legible, as regulatory compliance depends on proper identification and operational instructions.

Operational Testing Requirements

Functional testing ensures that all mechanical components operate correctly under normal conditions. Door operation should be smooth and consistent, with proper closing force that doesn't require excessive effort to open. The door must close completely from any open position, latching securely without gaps around the perimeter. Testing should include operating the door from various positions to verify consistent performance throughout its range of motion.

Self-closing mechanisms require specific testing to verify proper adjustment and timing. The door should close from a 90-degree open position within the specified time frame, typically between 3 and 10 seconds depending on the application. Closing speed must be consistent and not vary significantly between tests. Lock and latch mechanisms should engage properly without binding or excessive force, ensuring reliable security while maintaining emergency accessibility when required.

Maintenance Scheduling and Documentation

Preventive Maintenance Intervals

Establishing appropriate maintenance intervals depends on door usage, environmental conditions, and manufacturer recommendations. High-traffic areas typically require more frequent attention due to increased wear on hardware and sealing systems. Monthly visual inspections provide early detection of potential issues, while quarterly detailed assessments allow for more comprehensive evaluation of all components. Annual professional inspections by certified technicians ensure compliance with fire safety codes and identify issues that might not be apparent during routine checks.

Environmental factors significantly influence maintenance frequency requirements. Doors exposed to moisture, temperature extremes, or corrosive atmospheres may require more frequent inspection and component replacement. Industrial environments with dust, chemical exposure, or vibration typically accelerate wear patterns and necessitate adjusted maintenance schedules. Seasonal variations in humidity and temperature can affect door operation and seal performance, requiring additional attention during climate transitions.

Record Keeping and Compliance

Comprehensive documentation supports regulatory compliance and helps track door performance over time. Maintenance records should include inspection dates, findings, corrective actions, and personnel responsible for each activity. Digital systems can streamline record keeping while providing easy access for regulatory inspections and trend analysis. Photographic documentation of any defects or repairs provides valuable reference material for future maintenance decisions and warranty claims.

Compliance tracking ensures adherence to local fire codes and insurance requirements. Many jurisdictions mandate specific inspection frequencies and documentation standards for fireproof door systems. Failure to maintain proper records can result in code violations, insurance claim denials, or liability issues in case of fire incidents. Regular review of applicable standards helps ensure maintenance programs remain current with evolving requirements and best practices.

Common Issues and Solutions

Hardware Problems and Repairs

Door closer malfunctions represent one of the most frequent maintenance issues encountered in fireproof door systems. Hydraulic fluid leakage can cause inconsistent closing speeds or complete failure to close properly. Regular inspection of closer arms, mounting brackets, and adjustment screws helps identify problems before complete failure occurs. Replacement of hydraulic fluid and seal components often resolves performance issues and extends closer service life.

Hinge problems typically manifest as binding, squeaking, or improper door alignment. Lubrication with appropriate fire-rated lubricants resolves many hinge issues, while worn pins or bushings require replacement to restore smooth operation. Adjustable hinges allow fine-tuning of door position to maintain proper gaps and ensure complete closure. Spring hinges require periodic tension adjustment to maintain adequate closing force without creating excessive opening resistance.

Seal Degradation and Replacement

Intumescent seals gradually deteriorate due to environmental exposure, mechanical damage, and normal aging processes. UV exposure, temperature cycling, and humidity variations can cause seal materials to become brittle or lose their expansion properties. Regular replacement of seals ensures continued fire protection effectiveness, typically following manufacturer recommendations or when visual inspection reveals damage or degradation signs.

Proper seal installation requires attention to continuity, positioning, and compatibility with door hardware. Gaps or overlaps in seal installation can create weak points that compromise fire resistance. Seal replacement should use materials matching or exceeding the original fire rating specifications. Installation tools and techniques must prevent damage to seal materials during the replacement process, ensuring optimal performance when exposed to fire conditions.

Professional Services and Certification

When to Engage Specialists

Complex repairs and regulatory compliance issues often require professional fire door technicians with specialized training and certification. Structural damage, frame alignment problems, or fire rating concerns exceed typical maintenance capabilities and need expert evaluation. Professional services ensure repairs maintain the door's fire rating and compliance with applicable codes. Certified technicians possess the knowledge and tools necessary to diagnose complex problems and implement appropriate solutions.

Warranty considerations often mandate professional service for certain repairs to maintain coverage validity. Manufacturer warranties typically specify approved service providers and required procedures for covered repairs. Professional documentation and certification may be necessary for insurance claims or regulatory compliance verification. Annual professional inspections provide independent verification of door condition and maintenance program effectiveness.

Certification and Training Programs

Ongoing education ensures maintenance personnel remain current with evolving technologies, codes, and best practices. Industry organizations offer certification programs covering fire door installation, maintenance, and inspection procedures. Training programs typically include hands-on experience with various door types and hardware systems. Certification maintenance requires continuing education to stay informed about new products, techniques, and regulatory changes.

Internal training programs help building maintenance staff develop basic fire door knowledge while understanding their limitations. Proper training reduces the likelihood of inadvertent damage during routine maintenance activities. Staff should understand which activities they can safely perform and when to engage professional services. Documentation of training activities supports liability protection and demonstrates commitment to fire safety excellence.

Cost Management and Budgeting

Preventive Versus Reactive Maintenance

Proactive maintenance programs deliver significant cost savings compared to reactive approaches that address problems only after failure occurs. Regular maintenance extends component life, reduces emergency repair costs, and minimizes business disruption from door failures. Preventive programs allow for planned procurement of replacement parts and scheduling of maintenance activities during convenient periods. Early problem detection often enables minor repairs that prevent major component failures and associated costs.

Life cycle cost analysis demonstrates the financial benefits of comprehensive maintenance programs. While initial program establishment requires investment in training, tools, and documentation systems, long-term savings from extended door life and reduced emergency repairs typically provide positive returns. Insurance premium reductions may be available for facilities with documented fire safety programs, further improving program economics.

Replacement Planning and Budgeting

Strategic replacement planning helps avoid emergency procurement situations that often result in higher costs and extended lead times. Tracking door age, condition trends, and maintenance history enables informed replacement decisions. Budget planning should consider not only door costs but also installation, disposal, and temporary security measures during replacement periods. Volume purchasing opportunities may provide cost savings when multiple doors require replacement within similar timeframes.

Technology advancement considerations influence replacement timing decisions. Newer fireproof door designs often incorporate improved materials, hardware, and energy efficiency features that provide operational benefits beyond basic fire protection. Code updates may mandate certain features or performance levels that older doors cannot achieve through maintenance alone. Replacement planning should evaluate these factors alongside condition assessment to optimize timing and maximize value from replacement investments.

FAQ

How often should fireproof doors be inspected

Fireproof doors should undergo visual inspections monthly, with more detailed quarterly assessments and annual professional evaluations. High-traffic doors may require more frequent inspection due to increased wear. Environmental conditions, such as exposure to moisture or chemicals, can necessitate adjusted inspection schedules. Always consult local fire codes and manufacturer recommendations for specific requirements in your jurisdiction.

What are the signs that a fireproof door needs immediate attention

Warning signs include visible damage to the door surface, frame, or seals, improper closing or latching, gaps around the door perimeter, damaged or missing hardware, and doors that require excessive force to open or close. Any structural damage, warping, or separation of components requires immediate professional evaluation. Missing or illegible fire door labels also indicate the need for immediate corrective action.

Can building maintenance staff perform fireproof door repairs

Basic maintenance tasks like cleaning, lubrication, and minor adjustments can typically be performed by trained maintenance staff. However, component replacement, structural repairs, or any work affecting the fire rating should be performed by certified fire door technicians. Improper repairs can compromise fire protection and violate warranty terms. When in doubt, consult with professional fire door service providers.

How long do fireproof doors typically last with proper maintenance

Well-maintained fireproof doors can function effectively for 20-30 years or more, depending on usage patterns, environmental conditions, and quality of maintenance. Regular component replacement and proper care can extend operational life significantly. However, eventual replacement may be necessary due to code changes, technology improvements, or when maintenance costs exceed replacement benefits. Professional assessment can help determine optimal replacement timing.